The electronic products we depend on today would not be possible without fiberglass yarn, because of its inherent properties, which include low elongation, mechanical strength and thermal resistance.

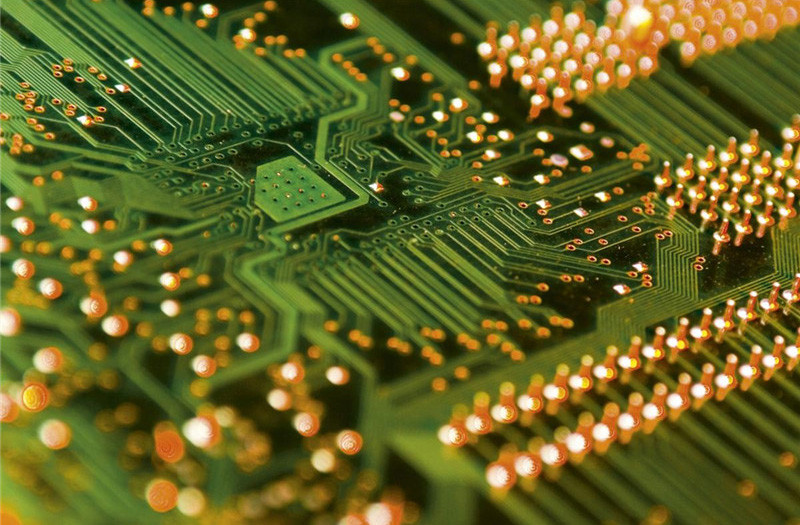

Electronic & PCB

The majority of printed circuit boards are based on various fabrics incorporating E-Glass yarns, which are layered and impregnated with a variety of resins such as epoxy, melamine, phenolic etc. The resulting laminate provides the backbone and/or substrate for the printed circuit board. Fiberglass yarn is used so the boards can meet critical electrical, corrosion resistance, thermal conductivity, dimensional stability and dielectric properties critical to the performance of the final parts.

GRECHO fiberglass yarns have been used extensively in this market for years, as the major weavers have demanded a high performance yarn in order to meet the stringent requirements of the industry. Fabrics that are using GRECHO fiberglass yarn are widely accepted throughout the world. There are thousands of products that incorporate our fiberglass products, including transformers, switches and relays.

Electrical

The same properties, which include low elongation, good mechanical strength, thermal resistance and excellent dielectric properties, make fiberglass a perfect yarn for electrical products.

Fiberglass yarns are braided, knit or woven into sleeving and tubing products that are widely used by motor and transformer manufacturers and are found in electrical, marine, defense, aerospace, electronic, and lighting markets.

Fiberglass sleevings are suitable for high and low temperatures, high and low voltages, as well as for abrasive and other physically demanding applications and hostile environments.

Fiberglass Banding tapes (b-staged resin bonded) are unidirectional fiberglass yarns to band and fix parts of motor coils and transformers to withstand the mechanical stress during operation.

The future will call for even more advances in fiberglass yarns in order to meet the increasing demands of highly advanced electronic and electrical components, and GRECHO is determined to meet those challenges.

Post time: Jul-19-2022