Production Process and Application of Fiberglass Mat Gypsum Board

Production Process

Material Preparation:The primary raw materials for producing fiberglass mat gypsum boards include gypsum powder, fiberglass mats, water, and other additives. Gypsum powder is made by heating natural or synthetic gypsum minerals, while fiberglass mats consist of woven glass fibers processed into a mat form through special techniques.

Mixing and Preparation:Gypsum powder is mixed with water to form gypsum slurry, with various additives added to enhance the gypsum board's performance. The fiberglass mats are cut to the appropriate size and placed onto templates on the production line.

Forming:The gypsum slurry is evenly applied onto the fiberglass mat, followed by placing another layer of fiberglass mat on top. Mechanical pressing is then used to compress the gypsum slurry, ensuring it bonds well with the fiberglass mats.

Drying and Curing:The formed gypsum boards are dried in a dryer kiln to ensure the gypsum is completely cured and achieves the required strength. The drying process requires strict control of temperature and humidity to ensure the quality of the gypsum boards.

Cutting and Surface Treatment:The dried gypsum boards are cut into different sizes and shapes as needed and undergo surface treatment to make them smoother for subsequent decoration and use.

Read moreApplications

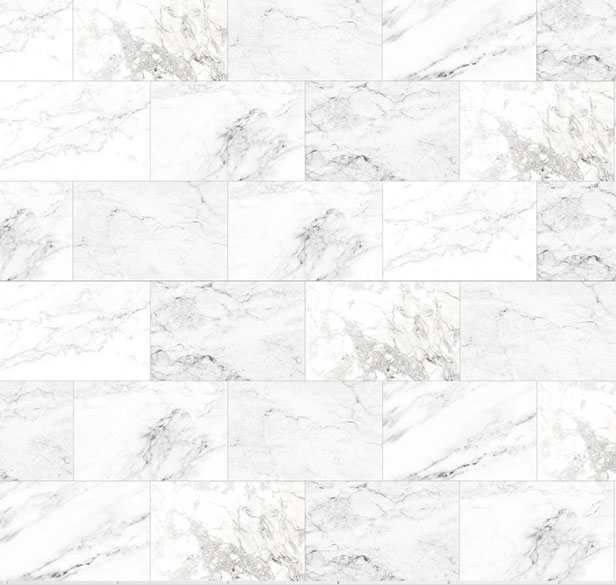

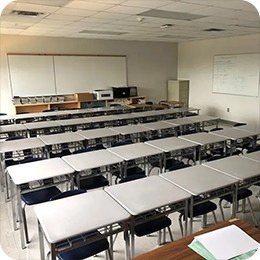

Fiberglass mat gypsum boards are widely used in construction and decoration fields, primarily for walls, ceilings, partitions, etc. Due to their superior performance, these gypsum boards are especially suitable for the following environments:

Residential and Commercial Buildings:Used for interior wall and ceiling decoration and soundproofing, providing excellent aesthetics and comfort.

Advantages

Compared to ordinary gypsum boards, fiberglass mat gypsum boards have the following significant advantages:

Enhanced Strength and Rigidity:The fiberglass mats reinforce the overall structure of the gypsum board, making it more rigid and compressive-resistant, less prone to deformation and damage, thereby extending its service life.

Excellent Fire Resistance:Fiberglass is a non-combustible material, which effectively enhances the fire resistance of the gypsum board. In the event of a fire, it acts as a flame retardant, improving building safety.

Superior Sound Insulation:The fibrous structure of the fiberglass mats effectively absorbs and blocks noise, significantly improving indoor acoustic environments and providing more comfortable living and working spaces.

Moisture and Mold Resistance:Fiberglass mats have excellent moisture resistance, preventing moisture ingress into the gypsum board and thereby avoiding mold and rot problems caused by humidity. This is especially beneficial in humid environments.

Lighter and Easier to Install:Compared to ordinary gypsum boards, fiberglass mat gypsum boards are lighter in weight, making installation more convenient and quick, reducing labor intensity and construction costs.

WHY CHOOSE GRECHO COATED FIBERGLASS MAT

Premium GRECHO Coated Fiberglass Mat

Conclusion

Owing to its superior performance in terms of strength, fire resistance, sound insulation, and moisture resistance, fiberglass mat gypsum boards have become the ideal material in modern construction and decoration. Whether in residential, commercial buildings, or public facilities, they can fully utilize their advantages to provide safer, more comfortable, and aesthetically pleasing environments. Compared to ordinary gypsum boards, fiberglass mat gypsum boards are undeniably the best choice for enhancing building quality and performance.